Filament winding

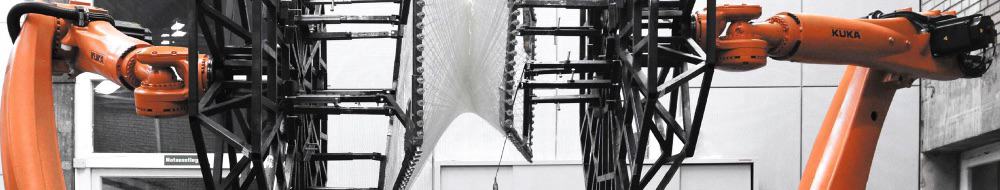

The filament winding process is mainly used in the production of hollow composite products with a circular cross-section. Filament winding consists of using a preform around which reinforcement fibres impregnated with matrix are winded. There are two types of use of this process: wet or dry. In the wet method the fibre absorbs the low-viscosity resin by passing through an impregnation and squeezing tank, while the dry method involves the use of pre-impregnated filaments. Once the matrix has hardened, the inner mandrel (mould) is removed and the component is obtained. Different types of resins can be used in this production process, depending on the intended use of the finished product. The result of the process is a part produced at low cost but with high structural rigidity.