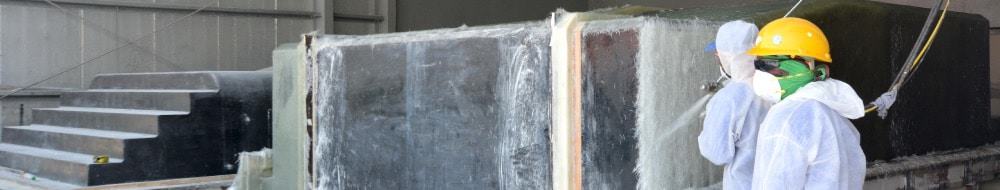

Spray-up process

The spray-up production process is one of the fastest and cheapest in the composite materials sector and is widely used in the production of large-sized components. The processing involves the use of an open mold inside which there is a layer of gelcoat which guarantees high quality in the coloring of the finished product. We then proceed with the spraying inside the mold of short glass fibers cut from a special gun and at the same time of catalysed resin. This technology allows the mold to be filled quickly and uniformly. Immediately after depositing the reinforcement, bubble breaker rollers or scrapers are used to eliminate the air introduced during processing. However, this technique has some drawbacks, the most important being the high weight of the component due to the high quantity of resin which impregnates the fibers and the poor mechanical and thermal properties.